Phone: (+27) 11 664-6370/6377/6099/6362

Email: beadsint@icon.co.za

VARIABLE SPEED-DRIVES OPTIONAL

| TYPE | VESSEL GROSS | MILL BASE | A | B | C | D | E | F | G | kw |

| CAPACITY | WORKING CAPACITY | |||||||||

| SSP 25 | 80 LITRES | 40 LITRES | 1885 | 1400 | 550 | 275 | 420 | 1085 | 486 | O7.5 |

| SSP 50 | 165 LITRES | 75 LITRES | 1850 | 1900 | 735 | 367,5 | 266 | 970 | 636 | 11 |

| SSP 100 | 500 LITRES | 150 LITRES | 2240 | 2220 | 876 | 438 | 280 | 1187 | 790 | 22 |

| SSP 300 | 1600 LITRES | 600 LITRES | 3350 | 3100 | 1365 | 627,5 | 176 | 1638 | 1140 | 55 |

BEADMILLS

| MODEL | DIMENSIONS | CAPACITY | ||||

| (A) HEIGHT | (B) WIDTH & DEPTH BASE | (c) HEIGHT TO SPOUT | WEIGHT KG | KW | OUTPUT LTRS/HR | |

| 02-P | 1550 | 0600 x 0500mm | 600mm | 310 | 2,2 | 012-125 |

| 03-P | 1740 | 0720 x 1760mm | 820mm | 420 | 5,5 | 030-170 |

| 08-P | 2064 | 1200 x 1200mm | 900mm | 2740 | 11 | 105-280 |

| 16-P | 2064 | 1200 x 1200mm | 900mm | 1210 | 18,5 | 230-600 |

HIGH SPEED DISPERSERS

AVAILABLE IN SINGLE, DUAL AND VARIABLE SPEED

| MODEL SSP | 15 | 18 | 20 | 22 | 25 |

| APPROXIMATE DISPERSION | |||||

| RANGE (BATCH SIZE) | 500-800I | 600-1000I | 700-1200I | 800-1400I | 900-1600I |

MIXERS AND LET-DOWN TANKS

AVAILABLE IN THE FOLLOWING CAPACITIES:-

| 600 | LITRES |

| 1000 | LITRES |

| 1500 | LITRES |

| 2500 | LITRES |

| 3000 | LITRES |

| 10 000 | LITRES |

ALL MIXERS ARE FITTED WITH DISHED OR CONICAL BOTTOMS AND ARE FREE STANDING OR MOUNTED IN WORKING PLATFORMS.

LOAD CELL MOUNTINGS OPTIONAL.

Disperser blades are used for most dispersing applications, since they produces high shear dispersion, pumping action, and size reduction – especially with heavy agglomerates.

The blades are made from high grade 304 Stainless Steel and are designed for far greater dispersion efficiency.

Immense care is taken to ensure that precise angles of the blade edges are maintained, as this is critical for high efficiency dispersion.

Most blades are stocked and available from 25mm (1inch) to 600mm (24inch) diameter, and are suitable for laboratory, to pilot lines, to full production.

Blades are typically held by top and bottom blade holders with 2 fasteners. Blade holders are recommended to maintain a rigid blade setting and restrict flexing of the blade itself during operation.

We are able to supply blades specially bored to fit most dispersers.

Our blades are used in inks, paint, coatings, adhesives, ceramic, rubber and chemical industries. They are designed to disperse, dissolve, or emulsify solid/liquid/gas materials.

WE OFFER A WIDE RANGE OF BLADE CONFIGURATIONS. PLEASE CONTACT US FOR OTHER BLADE DESIGN NEEDS.

|

|

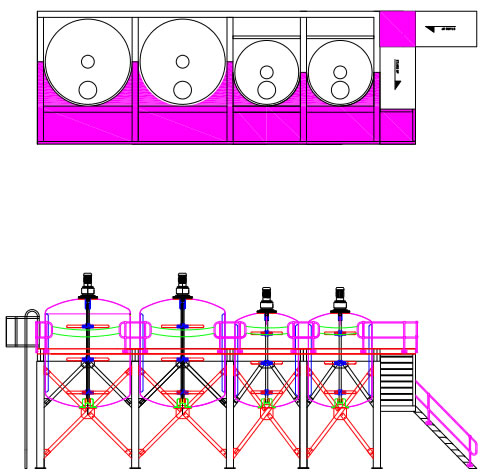

Tank platform and layout |